Weegexperts

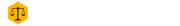

Automatic Labeling Machine Dibal LS-4500

Automatic Labeling Machine Dibal LS-4500

Request Quote

Couldn't load pickup availability

The LS-4500 automatic, high-speed weigh-price labeler is the perfect solution for efficient labeling. With a speed of up to 140 packages per minute, it can label fixed or variable weight and price information without interrupting the production line, thanks to dynamic weighing.

This versatile machine offers options for top and/or bottom labeling and supports a wide range of label sizes, ranging from L40 x W40 to L120 x W102 mm.

Enhance your labeling process with the LS-4500 and optimize your productivity.

Features:

- High-speed weighing: up to 250 ppm.

- Labeling fixed/variable weight/price.

- Weight discrimination through weight control.

- Generic traceability on the label.

- Customized to comply with EU Regulation 1169/2011 regarding food information.

- Barcodes: EAN-8, EAN-13, EAN-128, CODE 128, ITF-14, QR code, GS1 Datamatrix, and GS1 Databar (up to 4 barcodes per label).

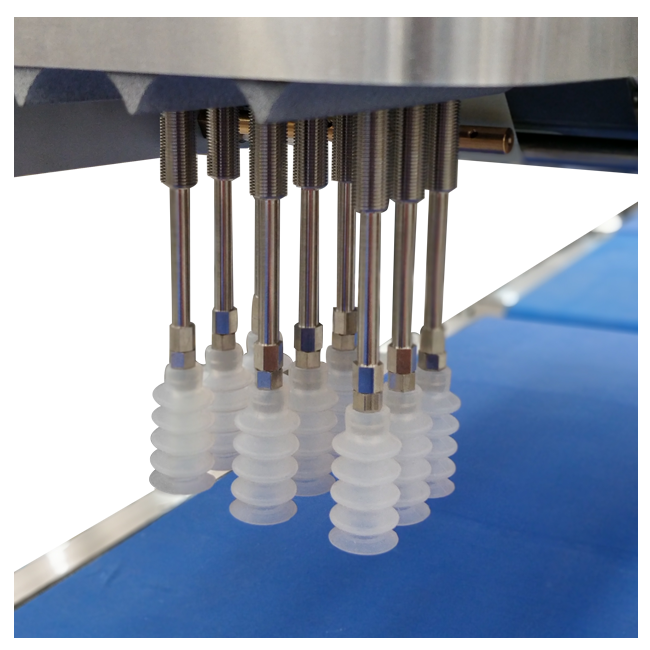

- Air applicator: maximum productivity.

- Adjustable cup applicators: a wider range of label sizes.

- MID certification: approved equipment.

Weighing:

Weighing type:

- Dynamic or static.

Ranges according to dimensions of the weigh belts:

- 3 kg / 1 g with conveyors of L300 x W200 mm.

- 6 kg / 2 g with conveyors of L400 x W280 mm, L400 x W400 mm, and L600 x W280 mm.

- 15 kg / 5 g with conveyors of L600 x W400 mm, L800 x W280 mm, and L800 x W400 mm.

Labeling System:

Print type:

- Direct thermal (DT) or thermal transfer (TT).

Print head:

- Long-lasting 4” (historical control).

Resolution:

- 8 dots/mm.

Speed:

- Up to 250 mm/sec.

Type of label applicator:

- Pneumatic piston. In top labeler, also the option of a 90º rotating applicator and "Air-jet®" air blowing. In bottom labeler, just by contact.

Position of the label applicator:

- Top, bottom, and/or side.

Labels:

- Dimensions: From L40 x W40 mm to L120 x W102 mm.

- Maximum width of backing paper: 115 mm.

- Inner diameter of the cardboard core of the label roll: Ø76 mm (the cardboard joint must be as wide as the backing paper).

Construction:

Structure:

- AISI 304L stainless steel and anodized aluminum.

Belts (all FDA-approved):

- Standard.

- High speed: super-adherent.

- Sliders: for extrusion areas.

Guides:

- AISI 304L stainless steel, anodized aluminum, and cestilene.

Control panel:

- Material: AISI 304L stainless steel.

- "Qwerty" keyboard and graphical LCD screen with backlight.

- Adjustable height of the top labeler from the Control Panel.

Communication to PC:

- Ethernet-TCP/IP.

- 2 RS-232.

PC Software:

- DIS: for equipment configuration, production data management, and backup (LBS).

- DLD: for graphic design of labels.

- Integration tools (see software section).

Power Supply & Compressed Air:

- Electric: 230 V / 50 Hz; 115 V / 60 Hz.

- Air: max. 150 l/min (at 6-8 bar).

Share

- Choosing a selection results in a full page refresh.